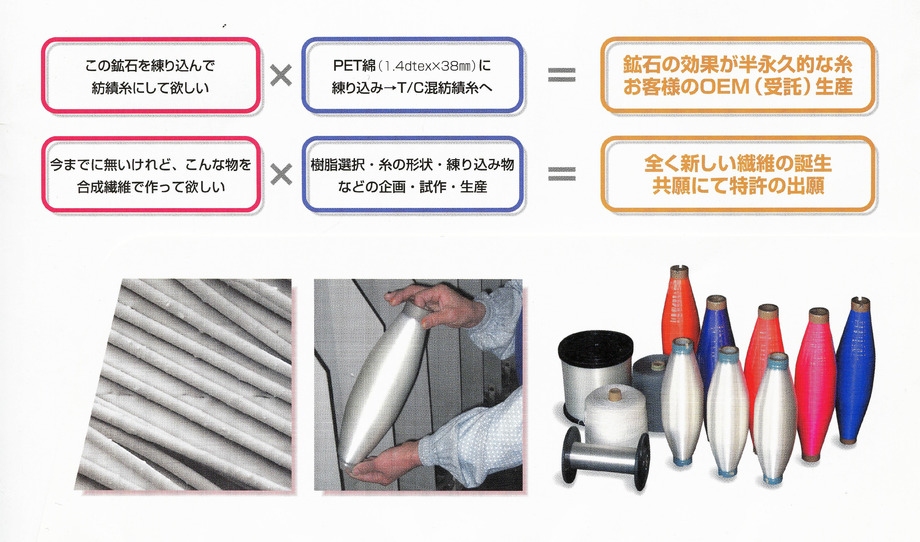

可依各種需求提供不同溫度、粗細之熱熔紗,在室溫下織造,可於定型時 或 染整時 或

以蒸氣、熱風 、紅外線 或其他方式昇高溫度,造成熱熔紗融化,進而提供黏著功能,

可提高品質、併縮短製程、單位成本低,符合經濟效應。

尼龍 (Nylon) 熱熔紗跟 聚酯纖維 (Polyester) 熱熔紗兩種材質皆可供您選用

以下為標準規格,也可提供客製化服務

50D, 70D, 100D, 140D, 200D

使用範例

鞋面纖維黏合.

b.強化布邊,避免毛邊,例如:地毯、方巾、蕾絲布 , 彈性織帶

花式紗、織帶、絨紗

當作芯紗,黏著外包其他材質

內衣肩帶上的蕾絲或特殊環狀設計,包覆內衣鋼絲的管狀織帶

增加布料的尺寸安定性、改善品質,例如:編繩、網布、繩索、彈性織帶…

預先織入布料中,後加工後再貼合其他布料,例如:褲腰頭、西裝褲